| Item # | Description | RPM | Tool | Travel | Year |

|---|---|---|---|---|---|

| 1 | TOYODA JTEKT 630S | 40-6000 | CT-50 / 60 ATC | 39.4X 33.5 X 29.5 | 2021 |

| 2 | ENSHU JE-80 HORIZONTAL MILL | 40-7000 | CT-50 / 40 ATC | 31.49 X 31.49 | 2001 |

| 3 | ENSHU JE-60 HORIZONTAL MILL FULL B AXIS | 40-13000 | BT-40 / 60 ATC | 24 X 24 X 27 | 2000 |

| 4 | MAZAK HTC-400 HORIZONTAL MILL | 40-10000 | CT-40 / 30 ATC | 24 X 24 X 27 | 1997 |

| 5 | MAKINO A51AX FULL B AXIS | 40-15000 | CT40 /132 ATC | 23.6 X 23.6 | 2012 |

| 6 | MATSUURA H.PLUS-300 PC26 PALLETS SYSTEM | 2005 | |||

| 7 | MATSUURA H.PLUS-300 | 40-14000 | BT40 / 240 ATC | 15.8 X 15.8 | 2002 |

| 8 | MATSUURA H.PLUS-300 FULL B AXIS | 40-14000 | BT40 / 240 ATC | 15.8 X 15.8 | 2005 |

-

ADEM providesTurnkey SolutionsFrom design, machining, prototyping to volume production

ADEM providesTurnkey SolutionsFrom design, machining, prototyping to volume production -

Novel CNC Machine ToolsInnovative TeamFacilitating your product manufacturing cycle

Novel CNC Machine ToolsInnovative TeamFacilitating your product manufacturing cycle -

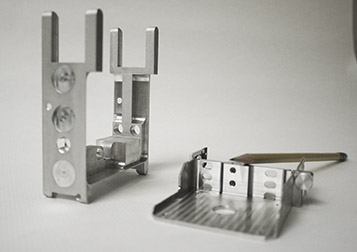

For Your Jig & Fixturing±.005mm PrecisionTight-tolerance work on Aluminum, Stainless Steel, Titanium, exotic alloys and wide variety of plastics...

For Your Jig & Fixturing±.005mm PrecisionTight-tolerance work on Aluminum, Stainless Steel, Titanium, exotic alloys and wide variety of plastics...

About Us

Located in a 30,000 s.f. facility in Silicon Valley, California, ADEM (Advanced Design, Engineering & Manufacturing), LLC was

established in 1997 and quickly earned the reputation as an advanced center of innovative technologies

and hi-tech solutions.

Located in a 30,000 s.f. facility in Silicon Valley, California, ADEM (Advanced Design, Engineering & Manufacturing), LLC was

established in 1997 and quickly earned the reputation as an advanced center of innovative technologies

and hi-tech solutions.

It is a unique company that offers not only manufacturing and assembly, but also superb design and engineering services. We provide turnkey solutions from design and prototype to high volume production.

In addition, ADEM will help with the design and manufacturing of special and/or automated fixtures for your assembly lines. As your manufacturing partner, ADEM will work with your engineering staff to develop production plans and provide parts that are accurate, on time, and within your budget.

Also, notably, we have close relationships with material suppliers and welding and finishing shops; as a result, ADEM is able to maintain a quick lead-time and competitive-priced even with small volume manufacturing for your prototyping or pilot production. We support a number of diverse markets including Semiconductor Equipment, Robotic Automation, Aerospace, Defense, Scientific Instruments, Medical and the Energy industry.

Equipment

Using the most advanced CAD tools, ADEM´s engineering department develops high-quality prototype systems. We have extensive experience with a variety of applications and with the latest CNC technology. Our facility is equipped with the most novel CNC machine tools, enabling close-tolerance

work (±.0001") on a wide variety of materials, plastics and machinable ceramics. We can accept various electronic files (solid models, DFX, etc.) and, after a prototype run, we are able to provide the manufacturing drawings.

Matsuura

Automatic cell with pallet system

Makino

Wire EDM Machine

Makino

a51nx Horizontal Machining 4 Axis

Enshu

Horizontal Machining Centers

MORI-SEIKI

Vertical Machining Centers

YCM

Vertical Machining Centers

Arika Seiki

Vertical Machining Centers

Fanuc RobotDrill

Vertical Machining Centers

Equipment List

| Item # | Description | RPM | Tool | Travel | Year |

|---|---|---|---|---|---|

| 1 | KITAMURA MY-3X FANUC | 40-10000 | CT40 / 20 ATC | 32 X 32 X 18 | 1997 |

| 2 | KITAMURA MY-3X YASNAC | 40-10000 | CT40 / 20 ATC | 32 X 32 X 18 | 1998 |

| 3 | MORI-SEIKI DURA VERTICAL 5100 | 40-10000 | CT40 / 30 ATC | 40 X 20 X 25 | 2010 |

| 4 | AKIRA-SEIKI SV-1300 | 40-8000 | CT40 / 25 ATC | 51.2 X 21.2 X 22 | 2000 |

| 5 | AKIRA-SEIKI PERFORMA V-4A | 40-10000 | CT40 / 25 ATC | 41.3 X 21.2 X 22 | 2000 |

| 6 | AKIRA-SEIKI SV-1000 | 40-10000 | CT40 / 25 ATC | 40 X 20 X 22 | 1998 |

| 7 | AKIRA-SEIKI APC-600 2-PALLETS | 40-10000 | CT40 / 20 ATC | 24 X 16 X 20 | 1997 |

| 8 | YCI SUPERMAX TCV 41A 2-PALLETS | 40-10000 | CT40 / 30 ATC | 50 X 22 X 24 | 2006 |

| 9 | YCI NSV 156A | 40-10000 | CT40 / 30 ATC | 60 X 25.6 X 24 | 2012 |

| 10 | YCM XV1020A | 40-10000 | CT40 / 30 ATC | 40 X 20 X 22 | 2006 |

| 11 | YCM XV1020A | 40-10000 | CT40 / 30 ATC | 40 X 20 X 22 | 2012 |

| 12 | YCM XV 560A | 40-10000 | CT40 / 21 ATC | 22 X 16 X 17.7 | 2012 |

| 13 | YCM NXV 1020A | 40-12000 | CT40 / 30 ATC | 40 X 20 X 22 | 2019 |

| 14 | HAAS 2SS | 40-12000 | CT40 / 20 ATC | 30 X 20 X 20 | 2012 |

| 15 | HAAS 3SS WITH ROTARY 4-AXIS | 40-12000 | CT40 / 25 ATC | 40 X 20 X 25 | 2013 |

| Item # | Description | RPM | Tool | Travel | Year |

|---|---|---|---|---|---|

| 1 | ROBODRILL T21iE | 40-10000 | BT30 / 21 ATC | 20 X 15.7 X 13 | 2007 |

| 2 | ROBODRILL T21iFa | 40-24000 | BT30 / 21 ATC | 20 X 15.7 X 13 | 2011 |

| 3 | ROBODRILL T21iFLa ROTARY 4-AXIS | 40-10000 | BT30 / 21 ATC | 27.5 X 15.7 X 13 | 2009 |

| 4 | ROBODRILL T21iFa | 40-24000 | BT30 / 21 ATC | 20 X 15.7 X 13 | 2012 |

| 5 | ROBODRILL T21iFa | 40-24000 | BT30 / 21 ATC | 20 X 15.7 X 13 | 2012 |

| 6 | ROBODRILL T21iFa | 40-24000 | BT30 / 21 ATC | 20 X 15.7 X 13 | 2022 |

| 7 | ARES-SEIKI R500 | 20-14000 | BT30 / 16 ATC | 20 X 15.7 X 13 | 2006 |

| 8 | MATRIX XR45 | 40-12000 | BT30 / 12 ATC | 12 X 12 X 13 | 2012 |

| 9 | MATRIX XR510 | 40-24000 | BT30 / 21 ATC | 20 X 15.7 X 13 | 2013 |

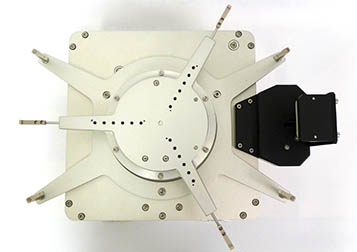

Horizontal Machine Center with Pallet

Working envelope of Φ530 x H760 mm (Φ20.86 x H29.92 in.).

Unlimited Possibilities of Engineering

ADEM - Your Engineering Partner

Years' Experience

CNC Machines

Experienced Staff

% of Customer Satisfaction

Services

From your parts' engineering, concept design, detailed design, machining, finishing, assembly , integration test and to pilot and volume manufacturing, ADEM assists you during the entire product manufacturing cycle.

Define Task

Understand client’s task mission to propose optimal manufacturing solutions.

Proof of Concept

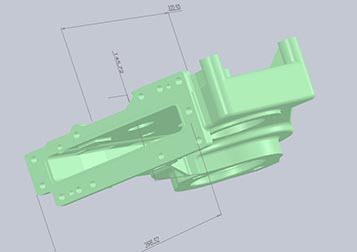

Create high level 3D model to get clients’ approval for prototyping

Detailed Design

Prepare 3D model for manufacturing

Machining

Use advanced CNC technology for machining with ± 5 µm (±.005mm) accuracy

Finishing

Welding and finishing outsourced to partners

Assembly

Kit and assemble even complex part.

Quality Control

Reliability and consistency guaranteed by our experienced QA team

Support

An extension of your engineering team

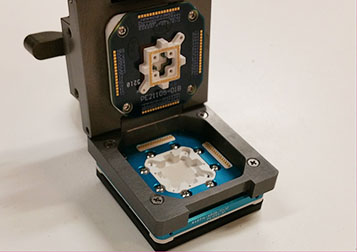

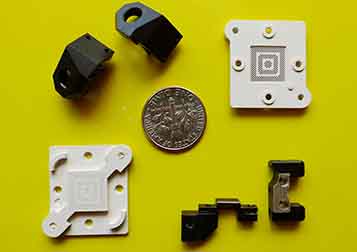

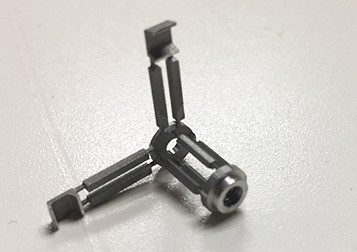

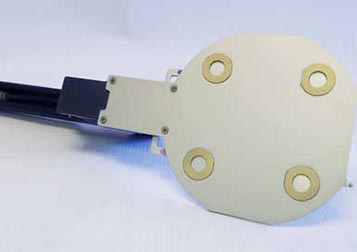

A CASE STUDY OF OUR WORK

1

Define Task

Tooling for client's thin & fragile MEMS wafer singulation automation

2

CAD Design

Study spec and constraint to create a wafer mask fixturing 3D model for client's approval

3

Machining

Use Fanuc RobotDrill with attached spindle 80,000 RPM, anodized

4

Assembly

Assemble fixture clamps and other sensing devices

5

Quality Assurance

Use CMM to assure the pick up tool and fixture reach ± 5 µm (±.005mm) accuracy

6

Integration Test

Client run test in their tool or applicaiton

7

Result

Meeting client's task objective

8

Pilot Production

Quote for client to decide move forward eith pilot run

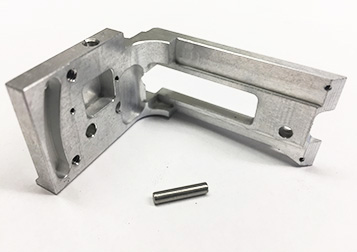

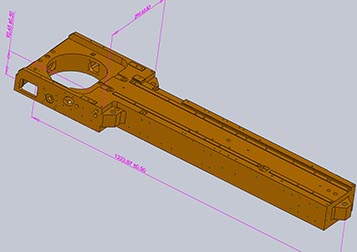

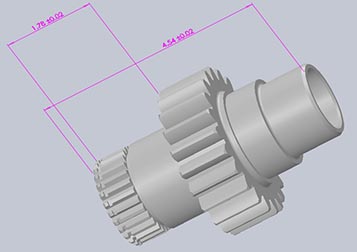

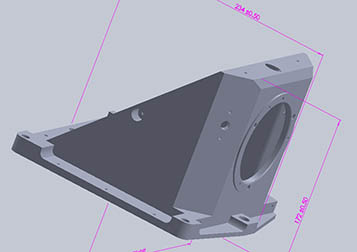

Portfolio

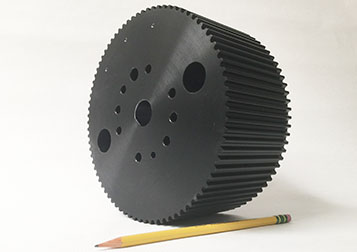

Equipped with state of the art CNC machine tools, including multi-spindle lathe and horizontal manufacturing cells, enabling tight-tolerance work (±.005mm) on Aluminum, Stainless Steel, Titanium, exotic alloys and wide variety of plastics...

Contact Us

Get in touch with us for your engineering and manufacturing needs.

Address

- 1040 Di Giulio Avenue

Santa Clara, CA 95050, USA

Call Us

- Call Us for a free quote!

- Phone: +1 (408) 727-8955

- Boris Kesil, Ext. 101

- Chun H.Yi, (408) 499-8000

Quick Contact

- boris.k@ademllc.com

- val_sokolsky@ademllc.com

- chun.yi@ademllc.com

- Skype: Boris.ksl